Coating Process

Coating Introduction (cathodic arc)

|

涂层种类

Coatings

|

涂层成分

Compo. |

涂层硬度

Hardness(Hv) |

涂层厚度

Thickness um |

摩擦系数

Friction coefficient |

最高应用温度

Thermal stability ℃ |

颜色

Color |

|

NAC-TiN Ge |

TiN |

2600 |

2-5 |

0.5 |

600 |

金黄 |

|

NAC-AlTiN D+ |

AlTiN |

3300 |

2-4 |

0.4 |

900 |

黑色 |

|

NAC-TiAlN |

TiAlN |

3200 |

2-5 |

0.4 |

800 |

紫色 |

|

NAC-AlTiCrN |

AlTiCrN |

3200 |

2-10 |

0.5 |

800 |

灰色 |

|

NAC-CrN Ge |

CrN |

2000 |

2-20 |

0.5 |

700 |

银灰 |

|

NAC-Cr-Multi |

CrN |

1700 |

2-8 |

0.5 |

600 |

银灰 |

|

NAC-CrN-LowT |

CrN |

2000 |

1-3 |

0.4 |

700 |

银灰 |

|

NAC-TiCN Ge |

TiCN |

3300 |

2-6 |

0.25 |

500 |

青灰 |

|

NAC-AlCrN |

AlCrN |

3300 |

2-3 |

0.5 |

1100 |

灰黑 |

|

NAC-AlTiCN |

AlTiCN |

3300 |

2-4 |

0.3 |

800 |

粉色 |

|

NAC-Speedexterior |

Si-Content |

4200 |

2-3 |

0.4 |

1100 |

古铜 |

|

更多个性化涂层设计… |

Coating Introduction (DLC)

|

涂层种类

Coatings

|

涂层成分

Compo. |

涂层硬度

Hardness(Hv) |

涂层厚度

Thickness um |

摩擦系数

Friction coefficient |

最高应用温度

Thermal stability ℃ |

颜色

Color |

|

WearGuard |

DLC |

1500-2000 |

1-6 |

<0.1 |

300-350 |

黑色 |

|

AbrasiveWearControl |

DLC |

1000-2000 |

30-80 |

<0.1 |

300-350 |

黑色 |

|

ArmorLube |

DLC |

1000-1500 |

6-10 |

<0.1 |

300-350 |

黑色 |

|

更多个性化涂层设计… |

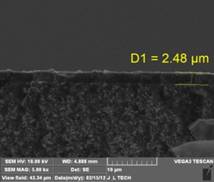

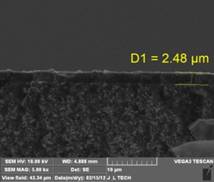

Coating Introduction (Hipims)

|

涂层名称

Coatings

|

涂层成分

Compo. |

涂层硬度

Hardness GPa |

涂层厚度

Thickness um |

粗糙度

Ra value |

最高应用温度

Thermal stability ℃ |

颜色

Color |

|

H-TiN |

TiN |

29 |

2.5 |

<40nm |

600 |

金黄 |

|

H-AlTiN 1 |

AlTiN |

33 |

3.0 |

<40nm |

900 |

黑色 |

|

H-AlTiN 2 |

AlTiN |

33 |

4.5 |

<40nm |

900 |

黑色 |

|

H-AlTiN 3 |

AlTiN |

33 |

6.0 |

<40nm |

900 |

黑色 |

|

H-CrN |

CrN |

24 |

4.0 |

<40nm |

700 |

银灰 |

|

H-TiAlSiN 1 |

TiAlSiN |

37 |

1.5 |

<40nm |

1100 |

古铜 |

|

H-TiAlSiN 2 |

TiAlSiN |

37 |

3.0 |

<40nm |

1100 |

古铜 |

|

更多个性化涂层设计… |